Draw Load Diagrams for Beams for Floor Framing Plan

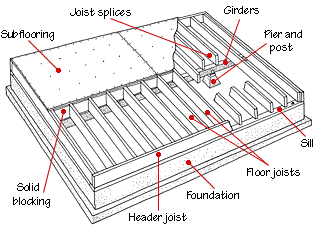

This illustrated guide offers diagrams to show how a typical forest-frame floor is congenital, from floor joists to subfloor and the sill plate.

Though some floors are built on a concrete slab flat on the basis, virtually floors are raised above the ground. Raised floors are more resilient under foot and provide access for heating equipment, insulation, plumbing, wiring, and other mechanical equipment.

A raised floor is synthetic with a wooden framework that bridges from one exterior wall to some other. This framework may or may not be supported intermediately past girders, beams, or walls.

On upper levels of a house, the underside of the floor framing by and large serves to dorsum ceiling materials. Ceilings are commonly built just similar floors, only they may be constructed of lighter materials because they're not intended to behave the aforementioned loads.

What Are Floor Joists?

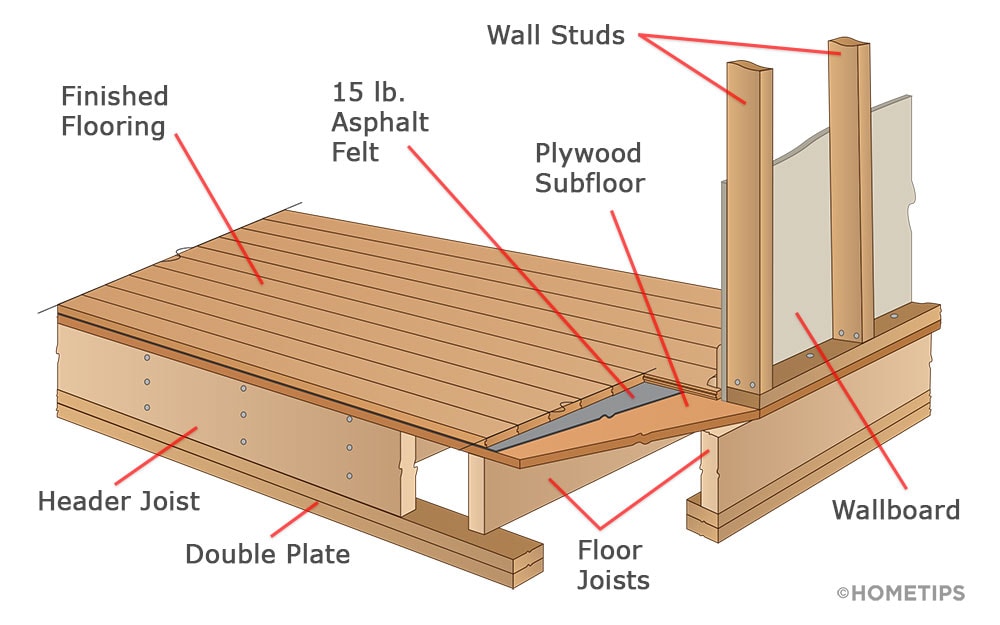

A floor's framework is made up more often than not of wooden joists that run parallel to one some other at regular intervals. Floor joists are typically two by 8s, 2 by 10s, or 2 by 12s; ceiling joists are normally 2 past 6s or sometimes two past 4s if it is an older home. Some newer homes take manufactured, I beam–shaped joists.

Floor joists, spaced on regular intervals, span the areas between supports such as walls, foundations, girders, and beams. Normal spacing is 16 inches "on middle" (from eye to middle), though some floors may have joists on 12-inch or 24-inch centers. Joist sizing and spacing are determined past building codes, which are based on engineering requirements. Joist headers run perpendicular to the joists, capping their ends.

Joists are spliced over beams or other supports. They may exist butted finish-to-terminate and connected with plywood gusset plates or lapped. Solid blocking or metal bridging prevents joists from twisting and helps distribute loads evenly.

Wherever an opening occurs, such as for a staircase, joists are doubled up at the perimeter and capped with perpendicular headers.

What Is a Subfloor?

Subflooring provides a base of operations for stop flooring and as well serves as a platform during construction. It may exist made of boards laid either at correct angles or diagonally across joists. Or the subfloor may be made of plywood or other panel products that are laid perpendicular to the joists.

A plywood subfloor has panels that are laid in a staggered mode, with the ends and edges butted together; the panels are nailed (and sometimes also glued with structure agglutinative) to the flooring joists.

The thickness and stiffness of the subfloor determine the types of finish materials that tin can exist laid on summit of it. If your house is built on a concrete slab, the slab can serve as a base for almost any type of flooring. Just, if your home has a plywood or board subfloor, it's important to bank check out the type and thickness of the fabric yous intend to use to determine what your limitations are. For case, a floor that is slightly flexible or springy is not suitable for rigid materials such as ceramic tile and stone because the grout or materials volition crack with movement.

What Is a Sill Plate?

At the foundation level, floor joists residuum directly on a sill that is treated with preservative so that contact with the foundation will not promote termites or rot. Their exact structure and connection with the wall studs depend on the method of framing that is utilized.

Featured Resource: Get a Pre-Screened Local House Framing Contractor

Source: https://www.hometips.com/how-it-works/floor-subflooring.html